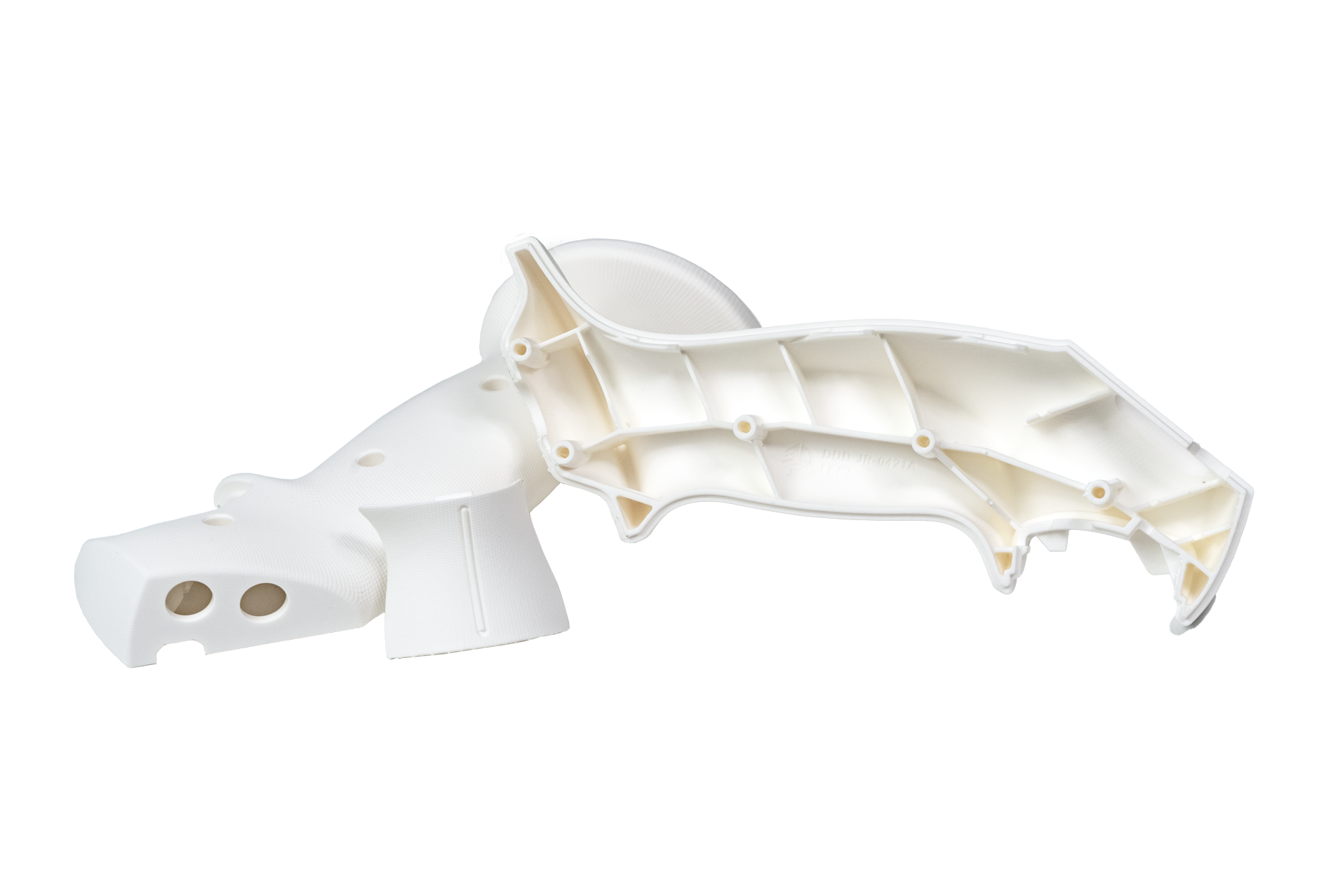

Tough White 60.

[Runs on Figure 4 DLP]

65A Shore Hardness Elastomer

Save on Tooling Costs and Time with Direct Production Plastic Parts

Figure 4® Tough 60C White is a versatile, biocompatible-capable production-grade white material with good impact strength, elongation, and tensile strength. It provides long-term environmental stability and long-lasting white color with an injection molded-like surface quality. This material is recommended for high mechanical load-bearing batch production medical parts that remain functional and stable for years.

This resin features a 65˚C heat deflection temperature and 23% elongation at break and is excellent for brackets, snaps, and clips due to a 7.1% elongation at yield. Fast print speeds and simplified post-processing speeds enable exceptional throughput.

Figure 4 Tough 60C White is tested to 8 years of indoor and 1.5 years outdoor mechanical performance per ASTM D4329 and ASTM G194 methods, ensuring that printed parts remain functional and stable for long periods in real-world conditions.

Applications

Clinical trials and medical devices such as tools, handles, and small plastic parts

Load-bearing parts such as handles, cranks, knobs, and levers

Structural parts like brackets, snap-fits, and custom fasteners

Small parts requiring detail and accuracy in consumer products, wearable devices, and general use

Functional prototyping and biocompatible end-user parts

Benefits

Long-term use parts for indoor and outdoor applications

No secondary thermal cure required

Clean, long-lasting bright white color

Excellent surface quality, accuracy & repeatability

Autoclavable

DOwnload data sheet >>>>

Features

Long-term indoor and outdoor environmental stability of mechanical properties and color; tested out to 8 and 1.5 years (respectively) per ASTM methods

Biocompatible-capable per ISO10993-5 and ISO10993-10*

65°C HDT at 0.455MPa

23% elongation at break

7.1% elongation at yield

34 J/m notched impact strength

1500 MPa tensile modulus

UL94 HB flammability

Sterilization through Autoclave

If you can dream it

we can make it.

At Fi Additive, we turn challenges into opportunities for innovation.

Our team has deep technical expertise and unique problem-solving capabilities to transform visions into tangible realities. If you have a tailor-made manufacturing job or a complex project that demands a hands on approach, we’ll work with you to ensure it’s a success.

Discuss your project with the team today