inconel 718.

[Runs on ProX DMP 320]

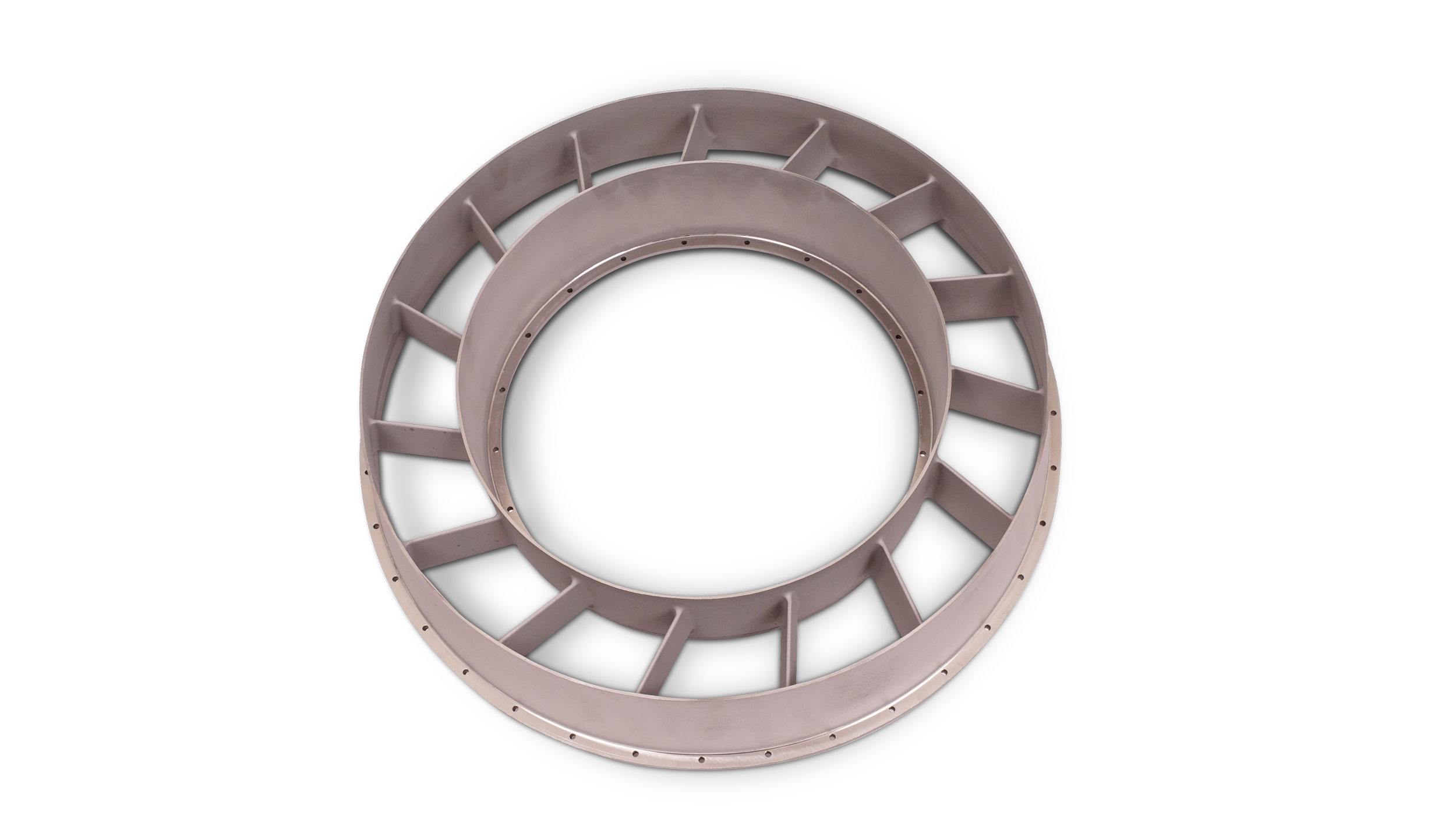

high temp applications

LaserForm Ni718 (A) is a nickel-based heat resistant alloy. This precipitation-hardening nickel-chromium alloy is characterised by good tensile, fatigue, creep and rupture strength at temperatures up to 700°C. Moreover it has outstanding corrosion resistance in various corrosive environments as well as excellent cryogenic properties.

Applications include

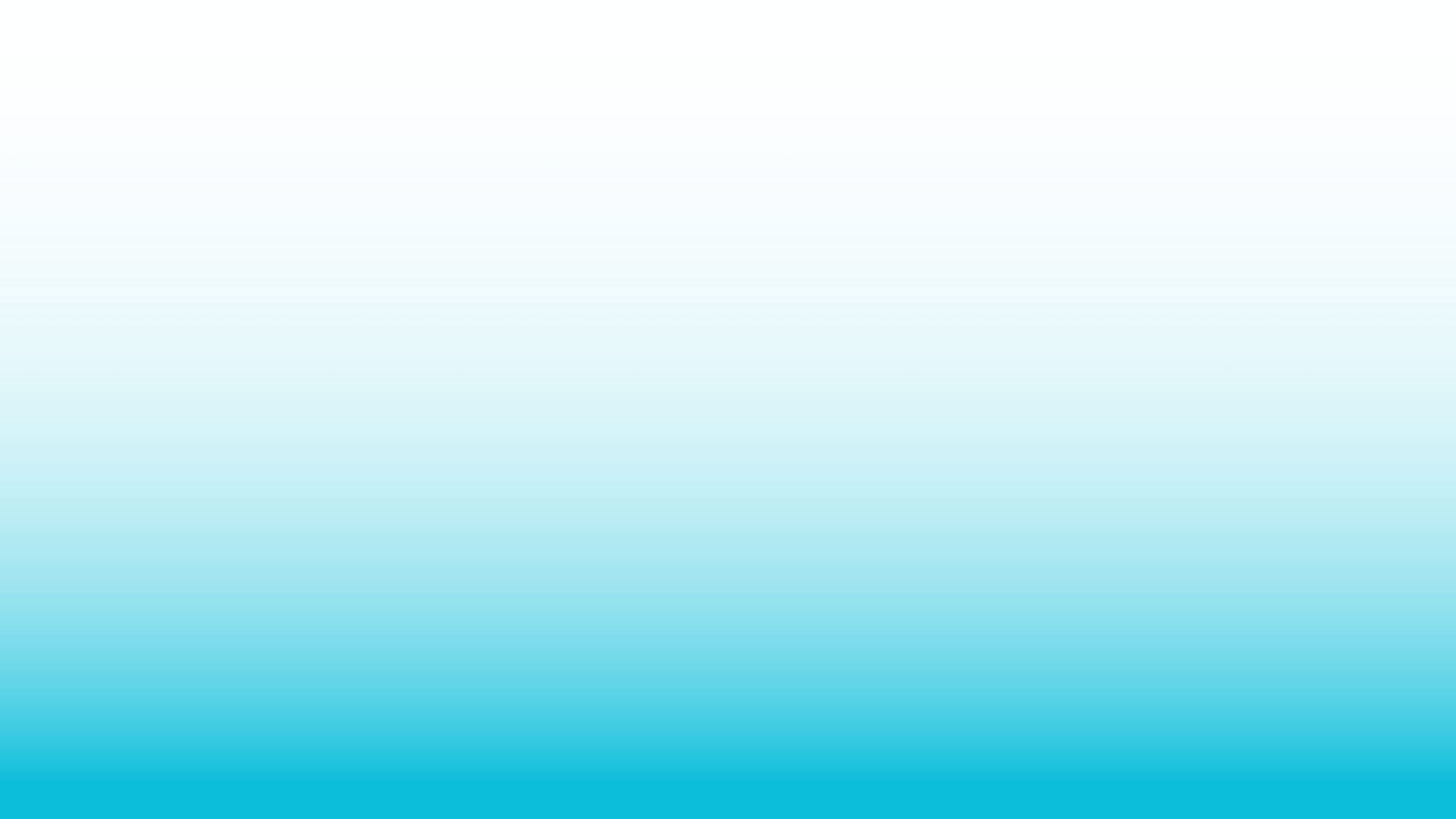

Gas turbine blades

Instrumentation parts

Power and process industry parts

Aerospace

High Temp

DOwnload data sheet >>>>

If you can dream it

we can make it.

At Fi Additive, we turn challenges into opportunities for innovation.

Our team has deep technical expertise and unique problem-solving capabilities to transform visions into tangible realities. If you have a tailor-made manufacturing job or a complex project that demands a hands on approach, we’ll work with you to ensure it’s a success.

Discuss your project with the team today