Your Vision

Expertly Crafted

into Reality

through 3d printing

We offer the most advanced additive manufacturing technology for your manufacturing and small-run needs. From aerospace to medical and manufacturing industries, our innovative thinking and manufacturing excellence can propel your business. There are no limits to what we can create.

Revolutionise Your

Prototyping & Production

Level Up Your Production with

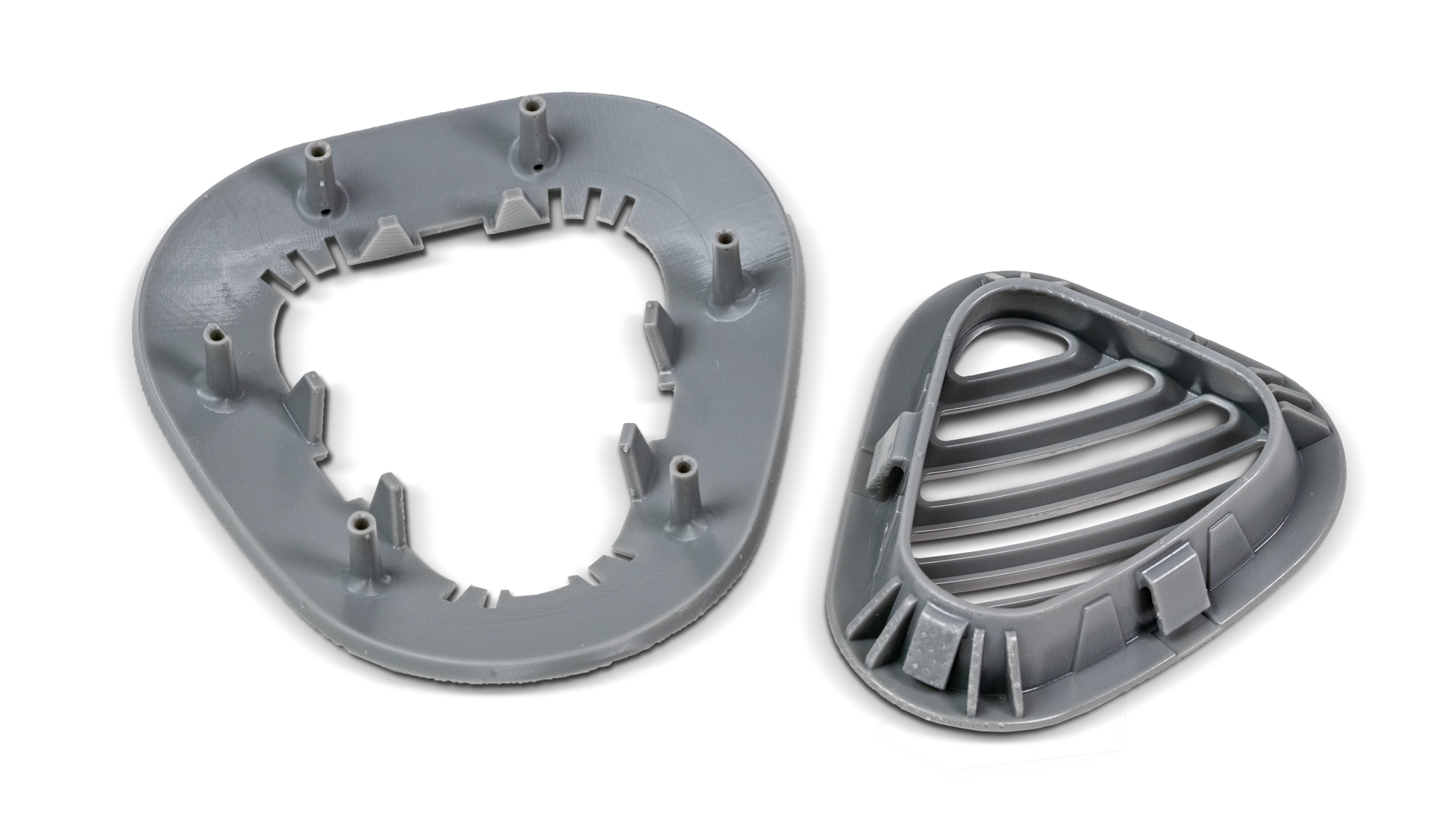

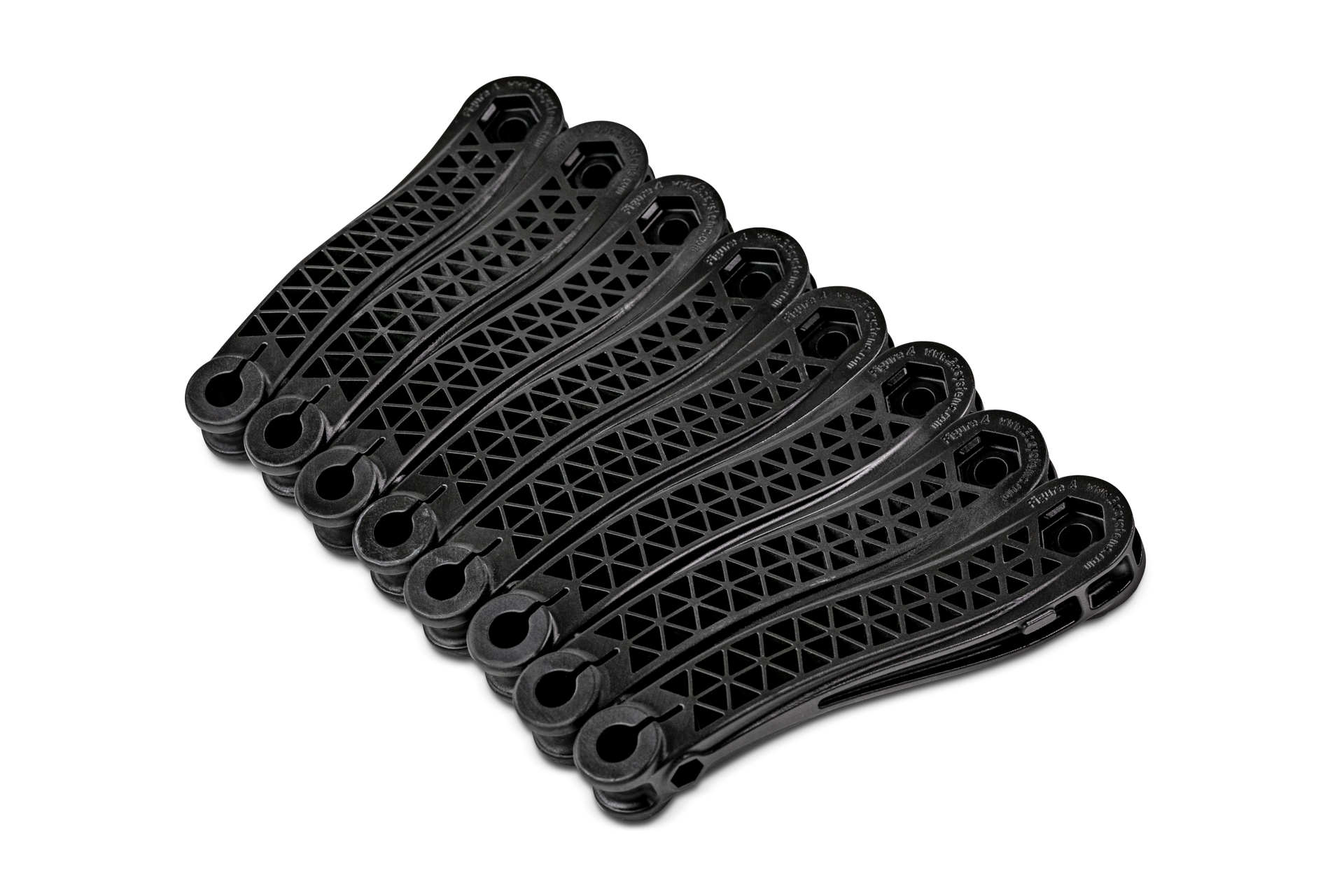

SLS Selective Laser Sintering

Create tough, durable parts from production-grade nylon materials, in small-batch, bridge, or custom manufacturing runs.

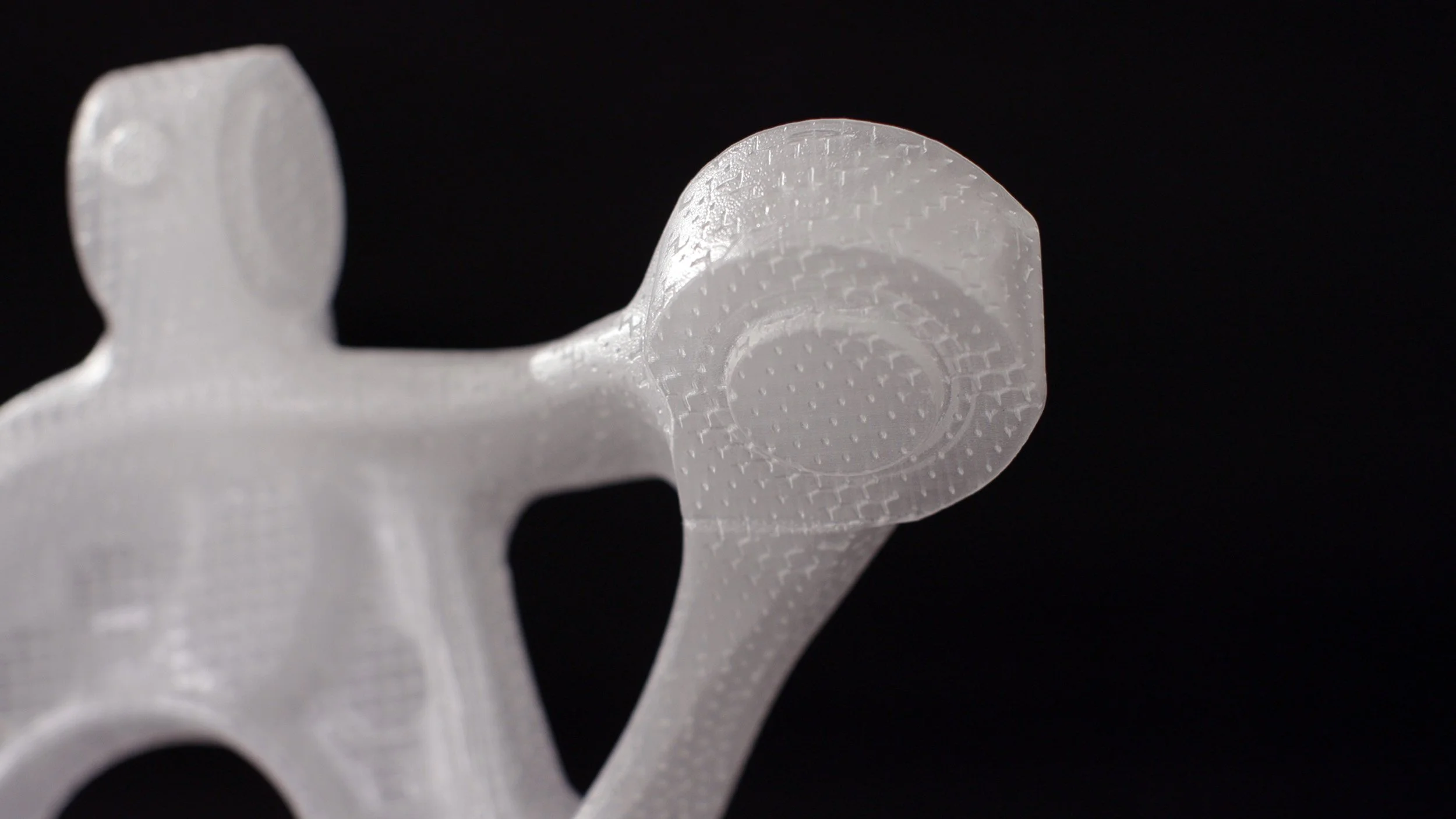

SLA Stereolithography

Produce highly accurate, isotropic, and watertight prototypes in a number of materials.

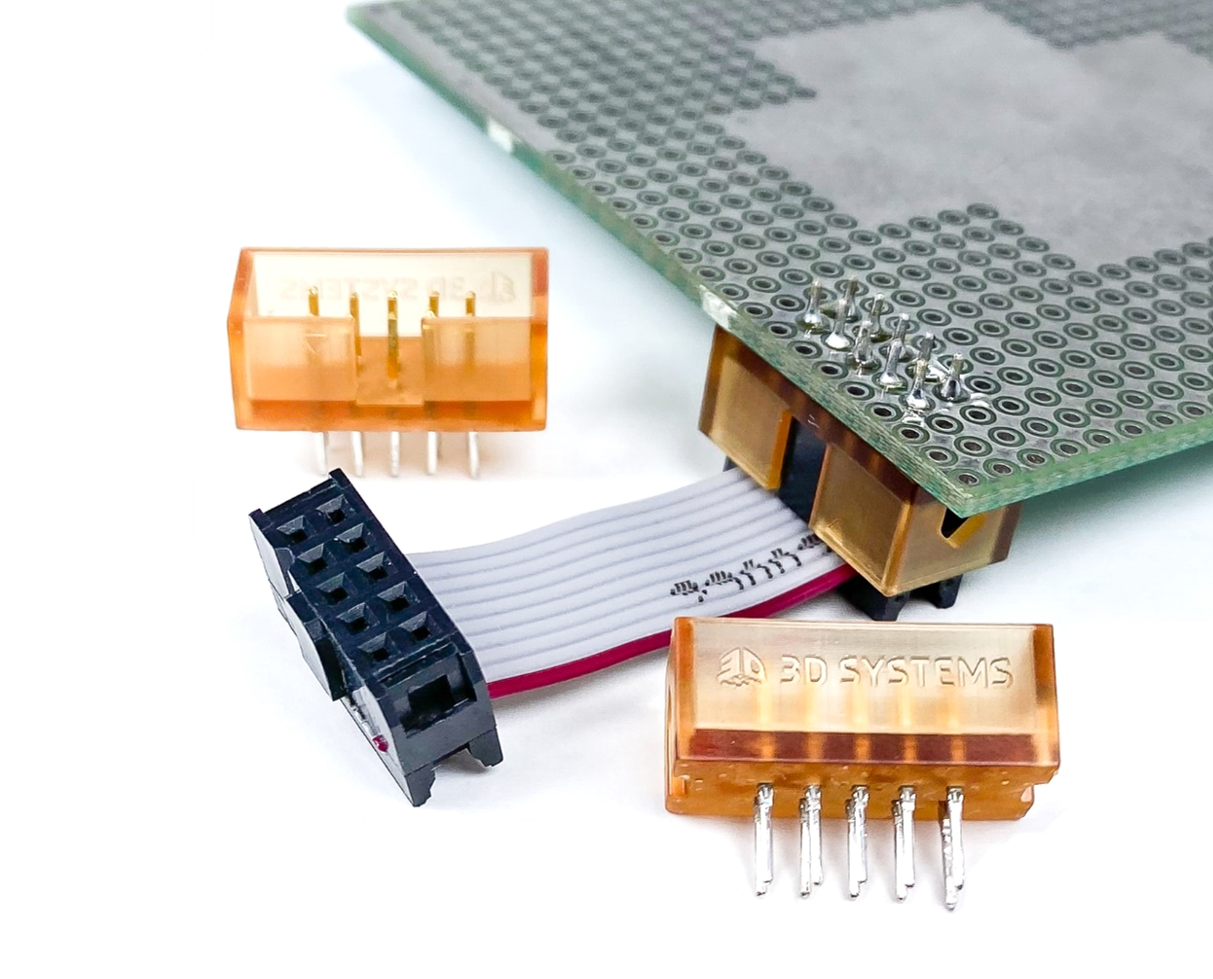

DLP Digital Light Processing

Print same-day resin prototypes and cost-effective, low-volume production runs, cured in minutes.

Post Processing

Smooth and seal the surface of your 3D printed polymer parts to be waterproof and air-tight, with an injection mould look and feel.

Metal Printing

Create complex, strong, high-performance parts, once thought impossible with Metal 3D Printing including intricate geometric designs.

3D Scanning

Take in-depth and accurate measurements of existing objects and parts, and create digital files of surfaces in real time.

>>Our Services

-

Quickly create prototypes or models. Easily improve an earlier prototype by changing aspects of its design.

Get into the details of Prototyping -

FI Innovations specialises in the production of functional parts that meet the rigorous demands of real-world applications. Whether you need a single component or a series for testing, our 3D printing services are engineered to deliver.

Get into the details of Functional Parts -

Step into the future of manufacturing with FI Innovations, where our 3D printing capabilities facilitate production at any scale. From small batches to larger production runs, we deliver with unmatched efficiency and quality.

Get into the details of Production -

At FI Innovations, design is at the heart of what we do. Our team of experts collaborates with you to bring your ideas to life, ensuring that every detail is considered and every possibility explored.

Unleash your creativity with our Design Services

THE MATERIALS.

FROM>>>>

PART

>>>> TO

PRODUCTION.

Machine Sales

3D Print Bureau

3D Printing and Additive Manufacturing experts,

Polymer or Metal, Single Parts or Thousands,

Our machine or Your Own.

If you can dream it

we can make it.

Bring your project to life in a few simple clicks with our intuitive self-service print job functionality.

Choose your preferred manufacturing technique, fill in the necessary details, and let our advanced technology handle the rest. It's straightforward, efficient, and designed to help you save precious time and resources.

At Fi Additive, we turn challenges into opportunities for innovation.

Our team has deep technical expertise and unique problem-solving capabilities to transform visions into tangible realities. If you have a tailor-made manufacturing job or a complex project that demands a hands on approach, we’ll work with you to ensure it’s a success.

Discuss your project with the team today