Digital Light

Processing [DLP]

Illuminate Your Ideas

Precision Printing with Every Pixel.

Print same-day resin prototypes and cost-effective, low-volume production runs, cured in minutes.

If we were to compare the Digital Light Processing (DLP) machine to some of our other advanced additive manufacturing technologies, the closest resemblance would be to the SLA. While they are much the same, the difference is that instead of using a laser to trace out the path of a layer while curing along the way, the Digital Light Processing technology uses a projected light source to cure the layer all in one go.

The functionality of the machine makes it suitable for manufacturing smaller parts with finer details, rather than those large-scale projects that require a high volume of units.

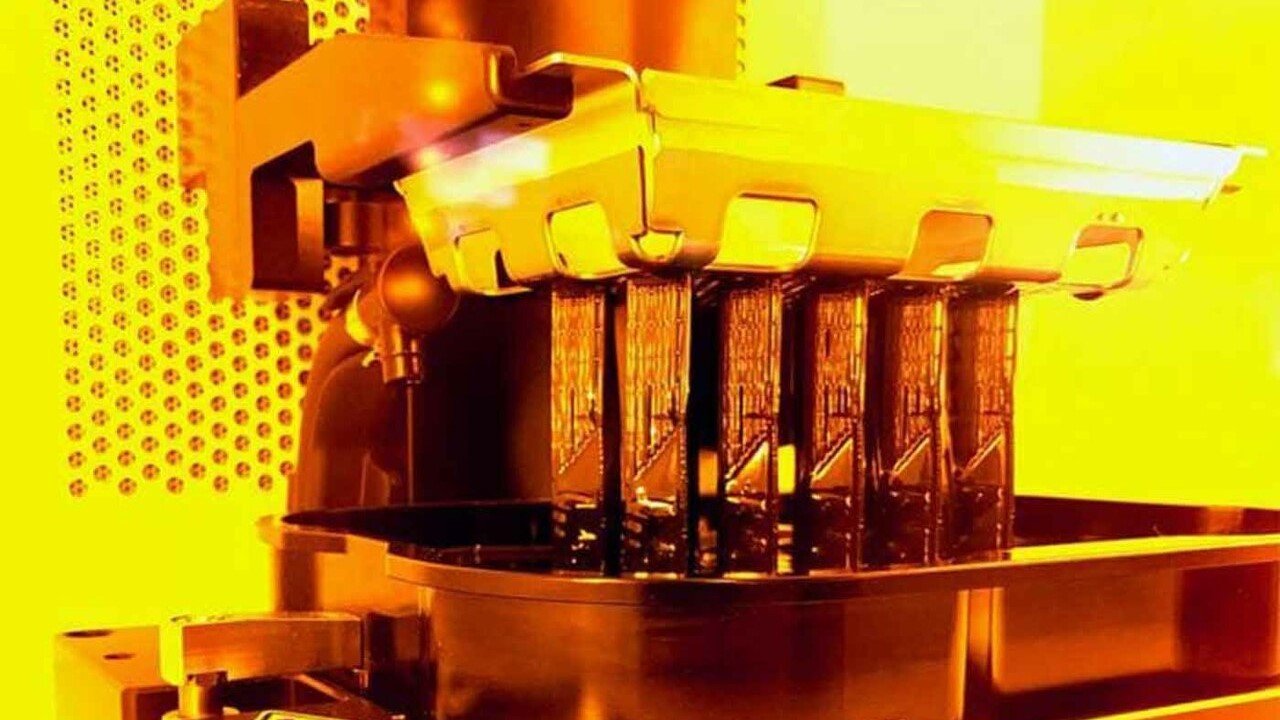

The DLP Machines

figure 4 polymer 3d Printer by 3D Systems

195mm x 123mm x 70mm Capacity

We have two machines onsite.

-

Combining 10 different materials , we can produce end use, medical-grade, rigid, flexibl and lastomers, biocampatible and food-grade compatible parts

-

Versatile, rigid heat-resistant material combines speed, applications strength, and excellent mechanical properties for toolless direct production of polymer parts.

-

Tool-less, same-day production

Direct production of small black plastic parts; examples include motor housings, connectors, snap-fits, automotive interior, and other general-use parts.

Digital production to replace injection molding or soft tooling processes

-

Natural, Post Processed

DOWNLOAD DATA SHEETS >>>>

If you can dream it

we can make it.

At Fi Additive, we turn challenges into opportunities for innovation.

Our team has deep technical expertise and unique problem-solving capabilities to transform visions into tangible realities. If you have a tailor-made manufacturing job or a complex project that demands a hands on approach, we’ll work with you to ensure it’s a success.

Discuss your project with the team today